Rod Pump

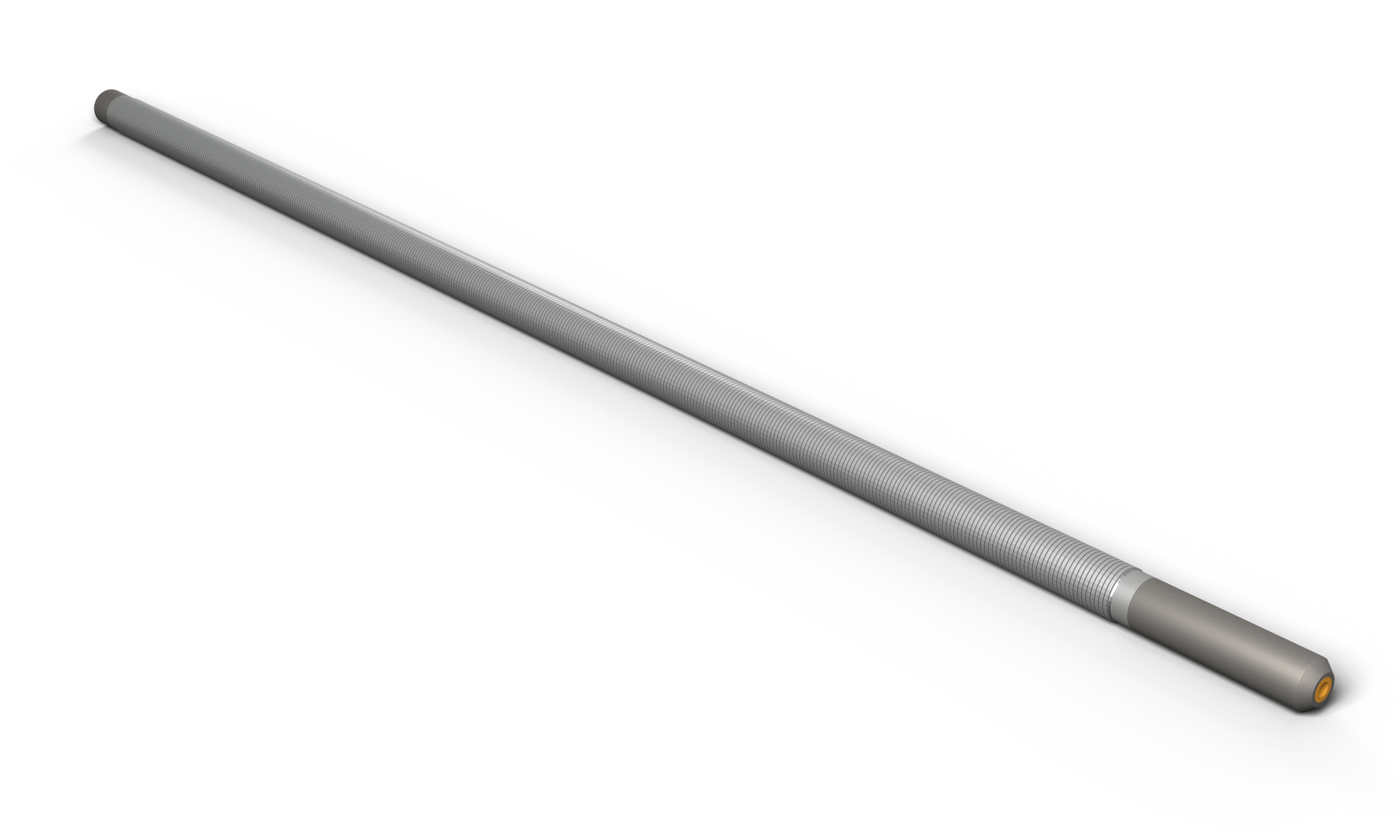

FatMan KI

LARGE BORE SCREENED GAS SEPARATOR

-

The FatMan KI is used in wellbore where sand will continually fill mud joints. The separator combines two types of solids separation for maximum fluid and solids separation. The outer housing is wire wrapped to help prevent larger solids from moving into the inner chamber. The larger screen allows gas to breakout away from the fluid through centrifugal and gravity separation while the hydro-cyclone at the bottom removes the suspended solids. The system can be run in tangent to create more screened surface area to prolong the screen from plugging.

-

Stainless steel wire wrapped screen

58% more screened area

338% larger separation capacityth any conventional gas separator

Hydro-Cyclone Separator for finer solids removal

Multiple separators can be added to increase capacities

Coming soon - Fatman b83 - currently in field trials

FAT MAN

HYDROCYCLONIC DEGASSER DESANDER

-

The Fat Man combines two types of separation for maximum fluid, gas and solids separation. The upper chamber allows gas to breakout away from the fluid through centrifugal and gravity separation while the hydro-cyclone at the bottom removes the suspended solids.

(Also available in a Lite Version without upper spiral)

-

Centrifugal and gravitational force separator - two types of separation

8% larger separation capacity - allows more gas to escape

Hydro-Cyclone separator - solids removal, coated and sized to production profile

Coated lower housing and inlet - longer lasting and less failure

Available for 4-1/2”+ wellbores

FAT MAN 239

HYDROCYCLONIC DEGASSER DESANDER W/ INTERGRATED TAC BYPASS

-

The Fat Man 239 integrates the FatMan hydrocyclonic gas separator with the TAC bypass for unrestricted flow above the separator. The Fat Man combines two types of separation for maximum fluid, gas and solids separation. The upper chamber allows gas to breakout away from the fluid through centrifugal and gravity separation while the hydro-cyclone at the bottom removes the suspended solids. The integrated TAC is now built into the body of the Fat Man and can incorporate any TAC on the market.

-

Unrestricted flow past the TAC

Centrifugal and gravitational force separator

8% larger separation capacity than competitors

Hydro-Cyclone separator for solids removal

Erosion and corrosion coated lower housing and inlet come standard

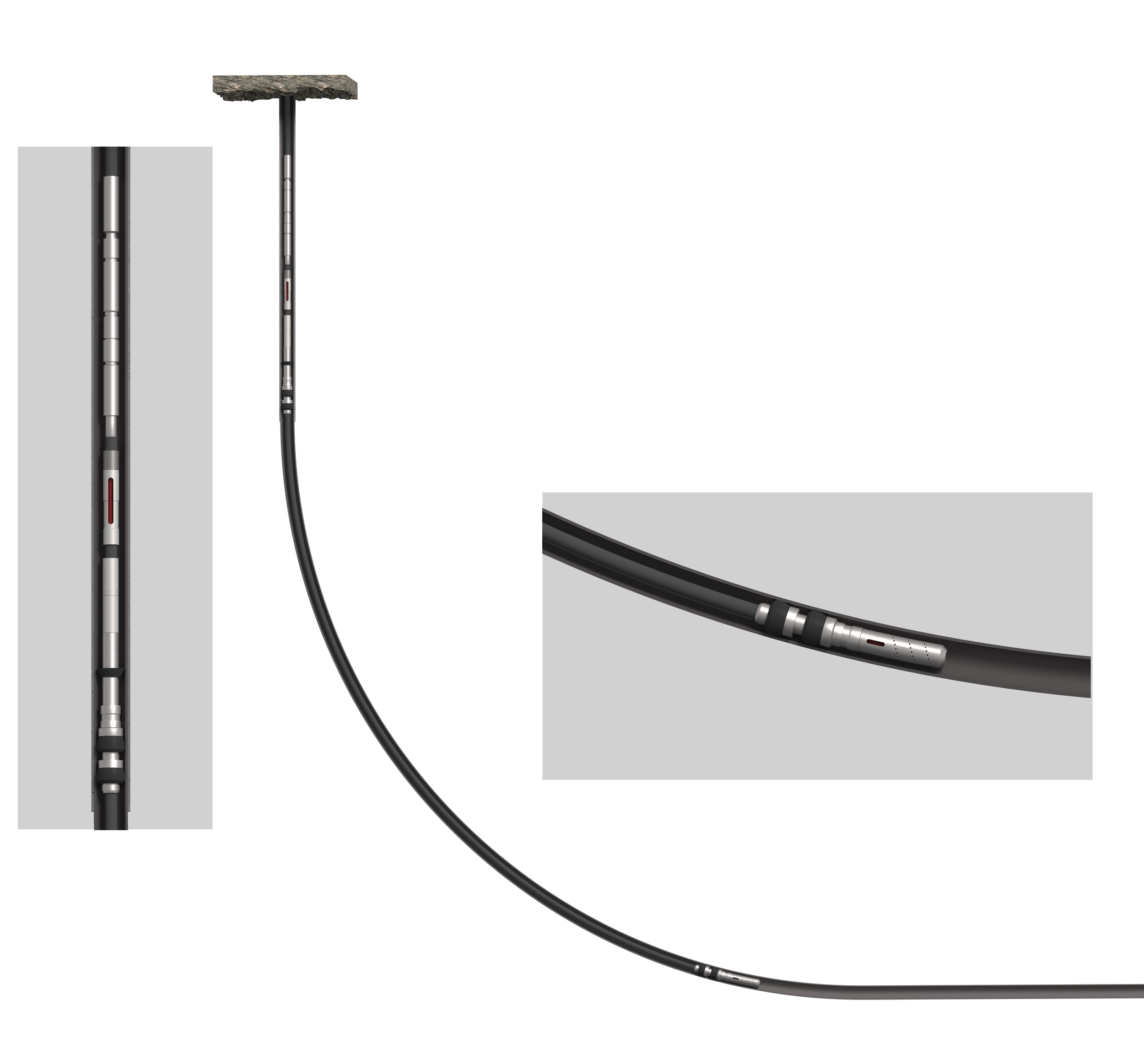

GADGET

HORIZONTAL PRODUCTION SYSTEM

-

The Gadget is a single-trip system of a series of tools used to produce horizontal wells more efficiently. This system creates a more optimal pump position that increases production and prolongs time between failures, leading to reduced LOE.

-

Increased production, reduced failures

Single-trip horizontal well production system

Supports optimal seat nipple positioning

Multiple gas separators available for the Gadget system

No welded connections

Debris barrier between gas separators and anchoring mechanism

Safer Auto-Jay mechanism to set and release system

LITTLE BOY

HIGH GLR / HIGH VOLUME DEGASSER DESANDER

-

The Little Boy, is a non welded separator that doesn’t require a packer and combines two types of separation for maximum fluid, gas and solids separation. The gap between the outer housing and the TAC allows gas to breakout away from the fluid through gravity separation while the TAC Bypass allows unimpeded flow both through and around the TAC.

-

Non welded separator

Gravitational force separator

Hydro-Cyclone separator for solids removal

Erosion and corrosion coated lower housing and IMU come standard

PATENT PENDING

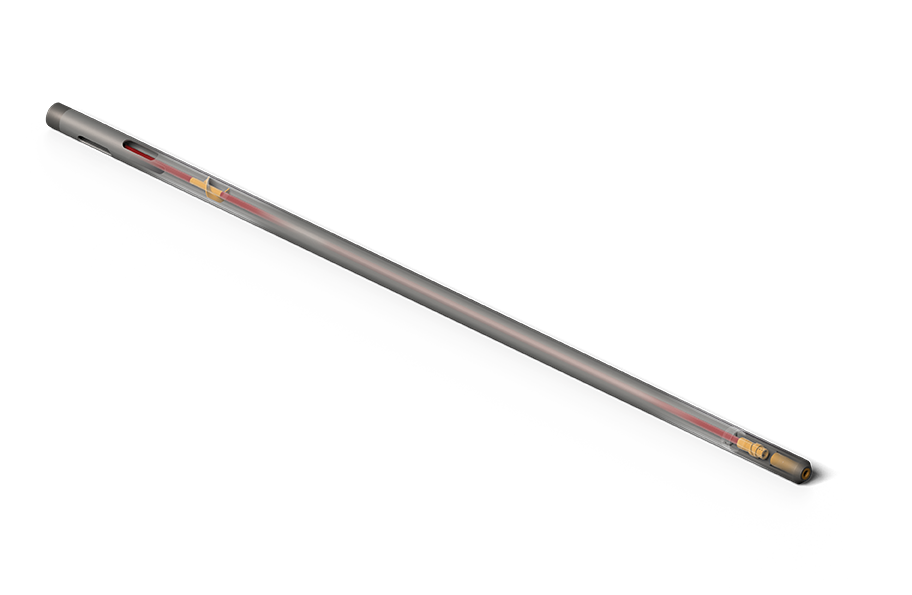

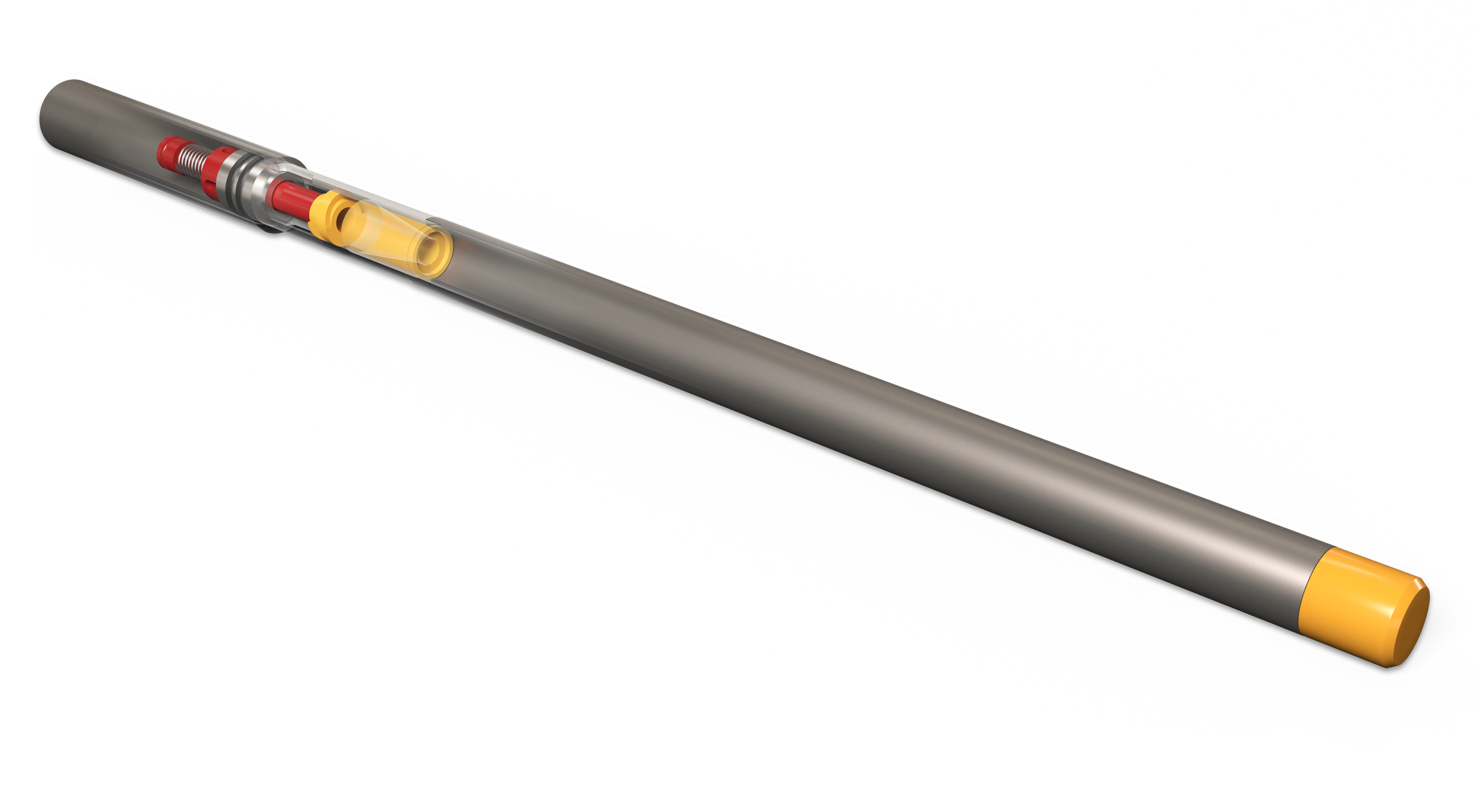

OPERATION SANDSTONE

ABOVE PUMP SAND COLLECTION CHAMBER

-

Operation Sandstone helps eliminate stuck pumps and scored pump barrels by removing solids fallback when the pump is not operating. The hollow rod collects solids as they fall back down hole when the pump is not activated, when the pump restarts, the solids are allowed to flow back out of the tubing to surface. Similar to what’s available for ESP’s redesigned for Rod Pump wells.

-

Prevent stuck pumps due to solids

Prevent pump wear by removing solids around pump barrel

Designed to prevent sand build-up on the rod annulus

Extendable length chamber to collect more solids

Porous section allows flow to move solids back up and out of the wellbore

PATENTED

TAC BYPASS

ROD PUMP GAS BYPASS

-

The TAC Bypass is used for high gas rod pumped wells where the TAC creates backpressure forcing gas into the gas separator. The system is set above the gas separator, below the seat nipple allowing gas to go around and through the TAC without putting additional backpressure on the fluid below.

-

Reduce backpressure on production system

Heavy walled housings

Short assembly

Reduce gas entrainment

Creates more flow area above the gas separator

PACKER STYLE GAS SEPARATOR

THIN MAN

-

The Thin Man is a packer style separator that creates more separation area compared to conventional dip tube separators. Fluid and gas is produced around the dip tube and exit at the top of the separator allowing an artificial sump to be created- the fluid falls towards the pump intake and the gas rises up the annulus. The lower bypass housing has 270° of bypass instead of drilled holes.

-

Better separation capacity than conventional separators

Creates an artificial sump to allow gas to rise and fluid to fall naturally

270° slotted lower bypass induces less shearing than drilled holes

Centrifugal stabilizer for standoff and increased breakout

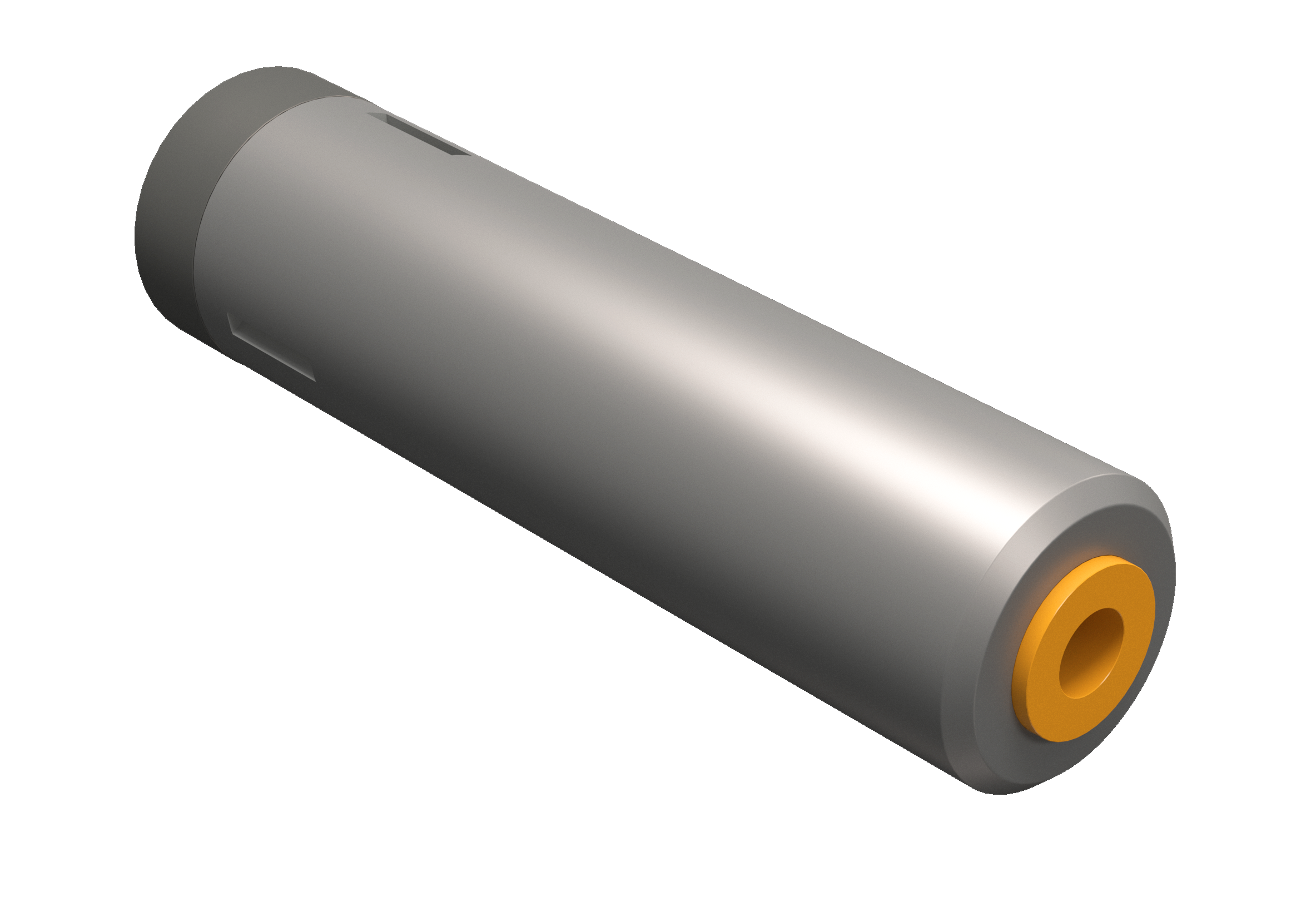

C-RAM

ABOVE ESP SAND COLLECTION CHAMBER

-

The C-RAM System is designed to prevent pump malfunctions caused by solids accumulation during periods of inactivity. The system features a hollow chamber within its housing that collects and holds solids when the pump is not in operation.

-

Features a large internal solids collection chamber to collect solids when the pump is not in use

Able to flow in both directions allows for injection treatments

Redressable internals can be cleaned and reused multiple times for added cost-effectiveness and convenience.

Available in L-80, P-110, 13Cr

PATENT PENDING

HIMARS

ESP Desander System

-

The HIMARS ESP desander system is a high-performance solution designed to tackle sand and other debris in oil and gas wells. By using hydrocyclonic style for media separation, the desander removes solid particles from the production stream, ensuring optimal sand control. Operating below the ESP, the system features a heavy walled slotted sub for unrestricted flow from the reservoir. A safety shear system ensures the ESP can be safely pulled in case the tailpipe becomes stuck.

-

Extend run times by reducing solids uptake

Safety release for stuck mud joints

Hydro-Cyclone separator for solids removal

Rate specific cyclonic spirals for better separation

Erosion and corrosion coated lower housing and inlet come standard

PATENTED

MK45

High Volume Desander

-

The MK-45 is a patented high-volume ESP desander designed to effectively remove sand and debris from oil and gas wells. Utilizing hydrocyclonic separation, it efficiently eliminates solid particles from the production stream, ensuring optimal sand control.

Reengineered from industrial desanders, it is specifically adapted for high-flow rate wells in the oil and gas. The MK-45 incorporates advanced erosion coatings along with nickel and stainless-steel materials, providing exceptional wear resistance and durability.

-

High efficiency solids separation

Rate specific inlets for optimized separation

Coated for erosion and corrosion

Flexible deployment, run with mechanically set or cup style packers

PATENTED

Gas Lift / Plunger Lift

ESP

GADGET - ESP

HORIZONTAL PRODUCTION SYSTEM

-

The Gadget is a single-trip system of a series of tools used to produce horizontal wells more efficiently. This system creates a more optimal pump position that increases production and prolongs time between failures, leading to reduced LOE.

-

Increased production, reduced failures

Single-trip horizontal well production system

Supports optimal pump placement

No welded connections

PATENT PENDING

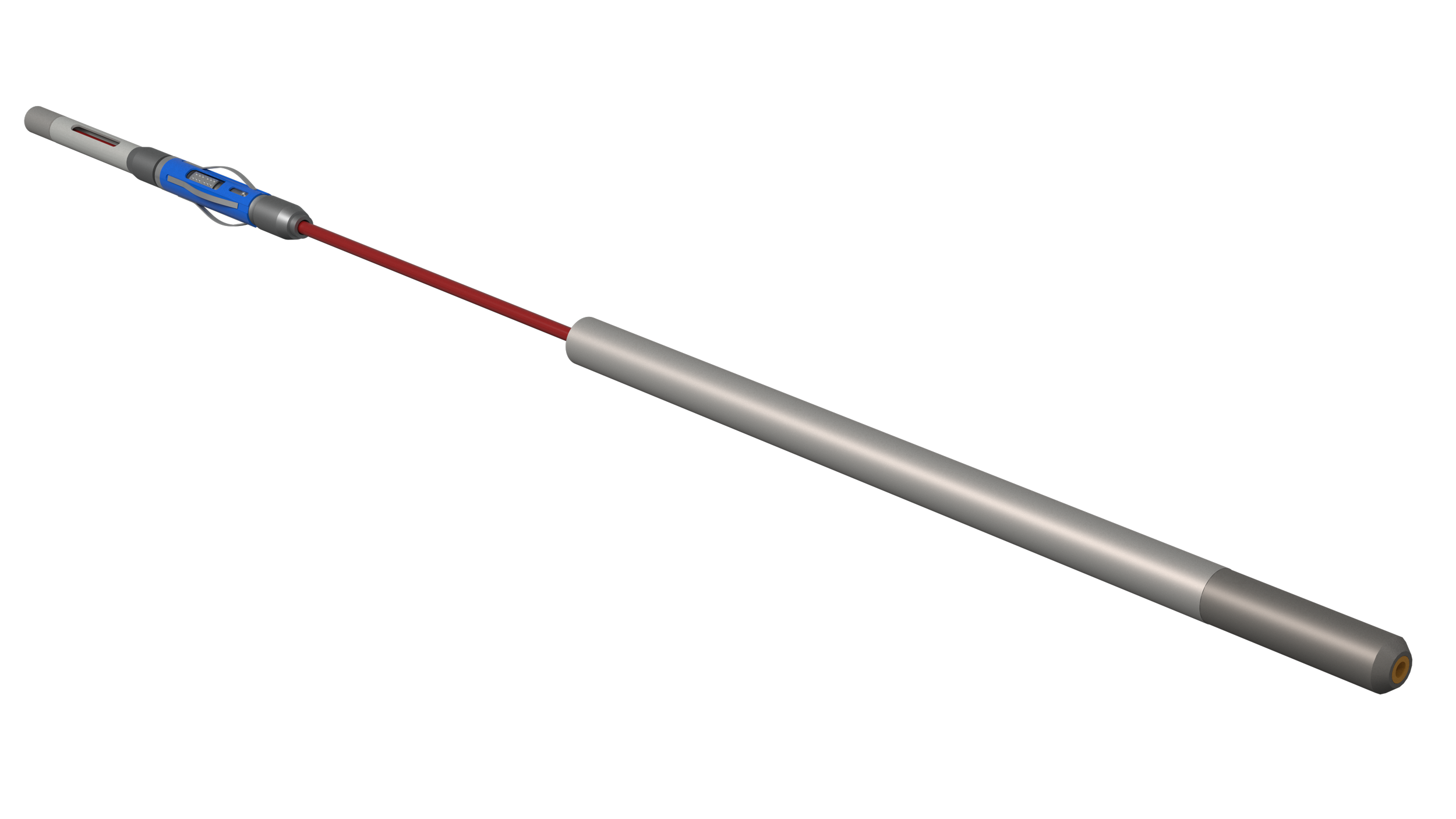

Dual Desander System for Rod Pump

HIMARS

-

The HIMARS desander system is a high-performance solution designed to tackle sand and other debris in oil and gas wells. By using hydrocyclonic style for media separation, the desander removes solid particles from the production stream, ensuring optimal sand control. Operating below the a gas separator, the system features a heavy walled slotted sub for unrestricted flow from the reservoir. A safety shear system ensures the ESP can be safely pulled in case the tailpipe becomes stuck.

-

Extend run times by reducing solids uptake

Safety release for stuck mud joints

Hydro-Cyclone separator for solids removal

Rate specific cyclonic spirals for better separation

Erosion and corrosion coated lower housing and inlet come standard

PATENTED

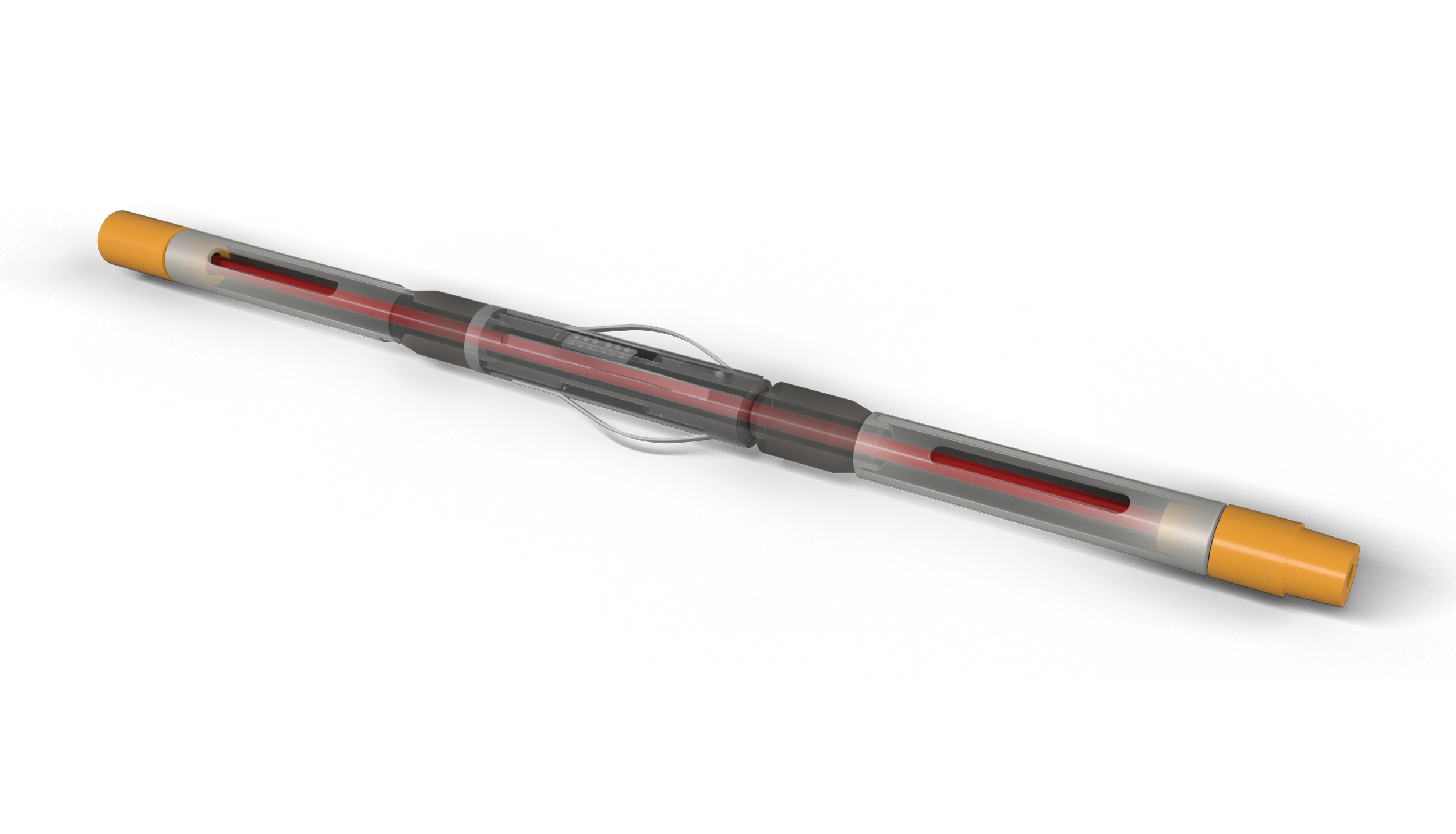

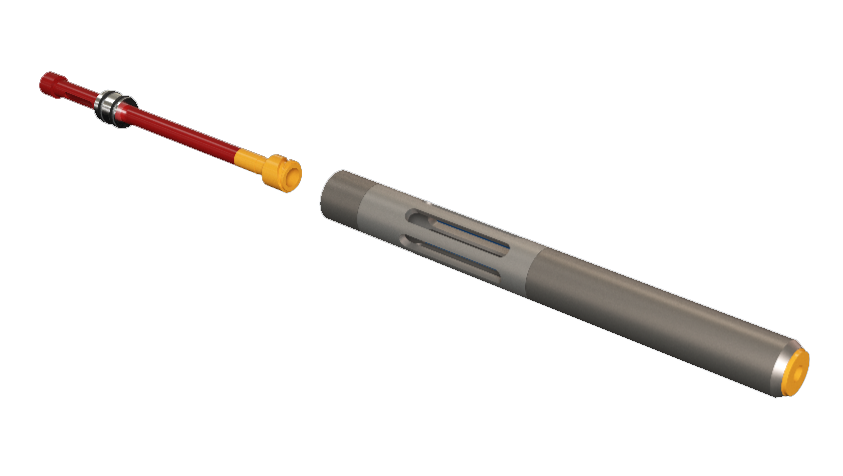

MARK 12

PLUNGER LIFT DESANDER

-

Mark 12 is a rig-less, slickline sand management system installed within the plunger lift. The desander is made up on surface, run in on slickline and set in existing profile nipples- removing solids from the production stream and collecting them downhole. Mark 12 is not a screen.

-

Proven and conventional sand separation method without using screens

Designed to be installed without pulling tubing

Installed with slickline

Designed for sandy plunger lifted wells

Reduce sand related failures and stuck plungers

PATENTED

TRIDENT II

PLUNGER LIFT/GAS LIFT DESANDER

-

Trident ll is a desander system made for the life of modern wells. As wells age from their initial tube up and move towards plunger lift, Trident ll allows unrestricted flow until a later point in life where the desander core is installed on slickline- removing the workover.

-

Prevent solids from moving uphole without interventions or screens

Reduce wear and tear on downhole and surface equipment

Simple installation on initial tube up

Desander core can be run at high rates

Reduce sand related failures and stuck plungers

PATENTED

Jeff Haddock Revolution Resources, Production Engineer

“The Gadget has allowed us to unload horizontal wells deeper while maintaining lower failure rates by enabling pumps to remain above KOP.”

Justin Lundquist Revolution Resources, Asset Manager